POLO-KAL XS assembly competition at the ISH Frankfurt

POLOPLAST exhibition stand, hall 6.0, stands A10 and B11

At the ISH Frankfurt 2017, POLOPLAST is presenting the outstanding POLO-KAL XS building drainage system with the brand new funTEC technology, and its complete POLO-KWL building ventilation System.

POLO-KAL XS ASSEMBLY COMPETITION

At the POLOPLAST exhibition stand, you can learn all about the unique product advantages of POLO-KAL XS and also win great prizes by taking part in the assembly competition. You’ll be won over by the tangible benefits to the user that can be gained by this extremely user-friendly and long-lasting pipe system, and its many advantages give it a clear edge over other building drainage pipes as far as users are concerned. Compare the systems for yourself and be inspired!

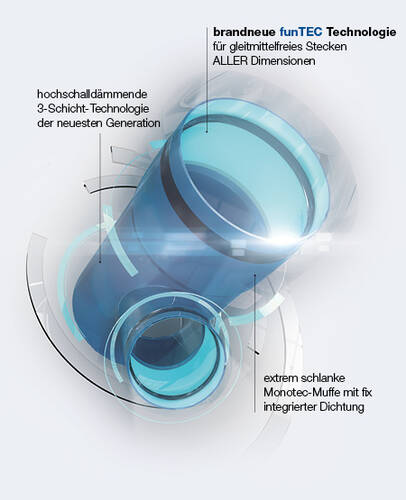

POLOPLAST uses the latest technology to revolutionise assembly: funTEC removes the need for lubricant when assembling POLO-KAL XS and gives you real satisfaction during handling.

As early as 2013, when the POLO-KAL XS building drainage system was released, POLOPLAST caused quite a stir with it in the industry. The latest generation of drainage pipes makes assembly much easier owing to the patented Monotec socket. Forgetting or losing O rings is no longer a problem thanks to the integrated seal.

The latest innovation by the Austrian pipe manufacturer has taken POLO-KAL XS to the next level. funTEC, the technology specially developed for this purpose, further improves the assembly properties. A fitter previously wouldn’t have even considered assembling pipes with large dimensions (DN 75-110) without lubricant. funTEC now makes this possible, and provides the user with many other advantages: it is considerably easier to construct branches, sockets are no longer stuck together by dried lubricant, and dirt can no longer cling to it. This means that funTEC really simplifies assembly and brings a lot more enjoyment to your day-to-day work.

The funTEC technology enhances the unique product advantages of POLO-KAL XS. The highly sound-insulating 3-layer technology in the latest generation provides excellent sound-insulating values and means that POLO-KAL XS is a very quiet pipe. The particularly slimline Monotec socket means that the pipe does not need to be chamfered after it is cut to length, and has an integrated seal that is already fixed in place. The ruler printed onto the pipes means you don’t need a measuring tape and pencil.

With this product, POLOPLAST has once again cemented its position as a leader in innovation in building drainage systems.

POLO-KWL – building ventilation system

The system from the quality leader

POLOPLAST has been working on the concept of controlled building ventilation systems for many years. The POLO-KAL® pipe system has long been used as an air distribution system of the highest quality, with impeccable performance in terms of hygiene.

In order to meet their customers’ needs, POLOPLAST is now offering a fully developed complete system from planning, to commissioning, servicing and cleaning, right through to the ventilation unit itself. The fact that all the components come from one source results in seamless high quality and perfect interaction between all the individual parts. Therefore, POLOPLAST also meets its high quality requirements in the area of building ventilation systems.

NEW

At the ISH Frankfurt, for the first time in Germany POLOPLAST is exhibiting the new POLO-AIR 390 with a rotary heat exchanger and integrated heat pump, including a cooling function for the summer and moisture recovery in the winter.

Optimal hygiene and easy to clean –

the POLO-KAL® air distribution system

POLOPLAST has been producing high-tech 3-layer plastic tubes with uncompromising quality for over 20 years. And it is exactly this that is of vital importance for a building ventilation system to function optimally: a circular pipe profile for minimal flow resistance and low power requirements from the fans. Ultra-smooth inner surface to prevent dust from sticking for lasting high performance and first-class air hygiene.

Energy-efficient and simple maintenance –

the POLO-AIR ventilation unit

Selecting the right ventilation unit always depends on the specific purpose. With various technologies and different dimensions, POLOPLAST’s ventilation units precisely cover all the requirements, from apartments, to detached and semi-detached houses, through to smaller commercial properties.

Save on energy costs with the POLOPLAST geothermal heat exchanger

To round off the complete system, POLOPLAST supplies the geothermal heat exchanger in two different variants: air or brine geothermal heat exchangers.

In a nutshell

Besides the many general advantages of a controlled building ventilation system, the complete POLOPLAST POLO-KWL system stands out particularly in the following areas:

- fully developed complete system, no additional pipe material or tools required

- easy assembly, and sources of faults are eliminated by reliable plug-in socket technology

- quick installation and no additional cabling work thanks to the plug & play system

- the highest quality, in accordance with DIN 1946-6, and hygiene certification

- a contact person from planning to commissioning and through to maintenance

- established POLOPLAST pipe technology with a unique 20 year guarantee*

* for the entire installed pipe System

Drinking Water Installation Systems POLO-ECOSAN und POLO-UV

Pure reliability – Made in Germany

POLOPLAST has developed innovative piping systems for water distribution. For many years, customers have relied on this know-how in the plastics branch. PP-R welded systems are the hygienically perfect, corrosion-free and sound-absorbing drinking water installation.

The multi-layer technology of POLOPLAST makes it possible to produce high-quality pipes that feature highly individual properties that are tailor-made to suit the particular field of application. The glass-fibre reinforced five-layer pipes of POLO-ECOSAN ML5, POLO-POLYMUTAN ML5 and POLO-UV ML5 excel in their performance.

POLO-ECOSAN

PP-R . PP-RCT

POLO-ECOSAN, the high-grade installation pipe made of polypropylene, and POLO-ECOSAN ML5, POLO-ECOSAN ML3 and POLO-UV ML5, the multilayer fibre-reinforced composite pipes, guarantee reliable, durable and flawless supply in interior installation systems. Wall thickness, pipe material and temperature range are the factors that decide the level of the resistance of a plastic pipe system to pressure. The pipe systems of POLOPLAST combine all these requirements.

POLO-UV

PP-R

The POLO-UV pipe system by POLOPLAST is a tested, UV resistant PP-R welded system. This composite material has been developed for this specific purpose, and its outer layer features outstanding resistance to UV radiation in outdoor installations. Many of POLOPLAST'S export destinations use this method of pipe laying. The system has passed the solar radiation tests conducted by an accredited laboratory and POLOPLAST can offer their customers increased safety by granting them a 10-year guarantee on resistance to UV radiation. Best quality – made in Germany!

POLO-ECOSAN und POLO-UV – the perfect solution:

- outstanding long-term resistance

- corrosion-free

- safe and homogeneous connections

- simple and fast assembly

- POLO-UV with UV protection